Synergy SPC Software Improves Productivity

Summary:

May 30, 2013 | Articles, Resources

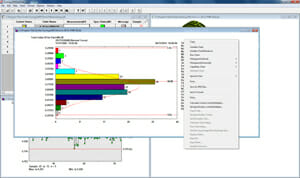

Time is money. Increases in personnel productivity can be a big cost savings. Synergy software enables you to automatically collect data and gives your operators real-time feedback so they can make adjustments instantly. Your operators are freed-up from paperwork, able to ensure that their data is error-free, prevent out-of-control conditions before they occur, and focus on their production jobs. Managers simultaneously monitor multiple processes at facilities and supplier locations globally. Your engineers instantly analyze the data, suggest process improvements based on historical data, prevent out-of-control or out-of-specification conditions from occurring, monitor production equipment and provide statistical process control (SPC) software data and analysis to management, customers or regulators in the specified format

Here are some Zontec customers who have experienced significant time savings with Synergy:

“What used to take a couple of days of work a week before using Synergy, now takes a push of a button. Now we have real-time information as we are weighing the bags,” said Glen Peters, Lab Technician for Polymerics.

“Synergy saves us about 45 minutes of the operators’ time from how we operated previously. When you calculate this across 22 machines that comes out to about 33 man-hours a day,” noted Scott Chambers, Quality Facilitator for Schoeneck Containers Inc.

“We’re running 2 shifts with 2 quality people. It used to take 3 quality people. Implementing Synergy is saving us 14 hours a day,” said Wayne Maurer, Quality Manager for MET Plastics.

“As Quality Manager, what used to take a day’s worth of work to determine our Cpk’s and our Ppk’s is now just a click of a mouse. Now I have a tool that enables me to analyze, report, and explain in an efficient manner the current state of our processes. I have the data to show where we can improve our processes,” commented Aditya Deshpande, Quality Assurance Manager for Cumberland Plastics Solutions.

“We also estimate we are saving approximately 30% of an operator’s day due to data entry. Using Synergy 2000 we have eliminated data entry errors. We are able to measure that a part completely and save 30% of our time doing it,” remarked said Ted Black, QA Manager for the A.P. Plasman-Windsor Plant.

“Since implementing Synergy, the reduction in paperwork is huge. Before every entry took us about 3-½ minutes per sample size and now it only takes us less than 30 seconds. There are 240 critical characteristics we could be measuring at any given time. Using Synergy has saved us about 12 man-hours per day,” said Douglas Winfrey, Director of Quality for United Gear and Assembly.

Increased personnel productivity alone can justify investing in Synergy software.

Choose from our product suite for the software package that fits your business.